Laser-Material Interactions in Metal Additive Manufacturing

🔬 Examining Laser-Material Interactions for AM Monitoring & Control

🌟 1. Introduction

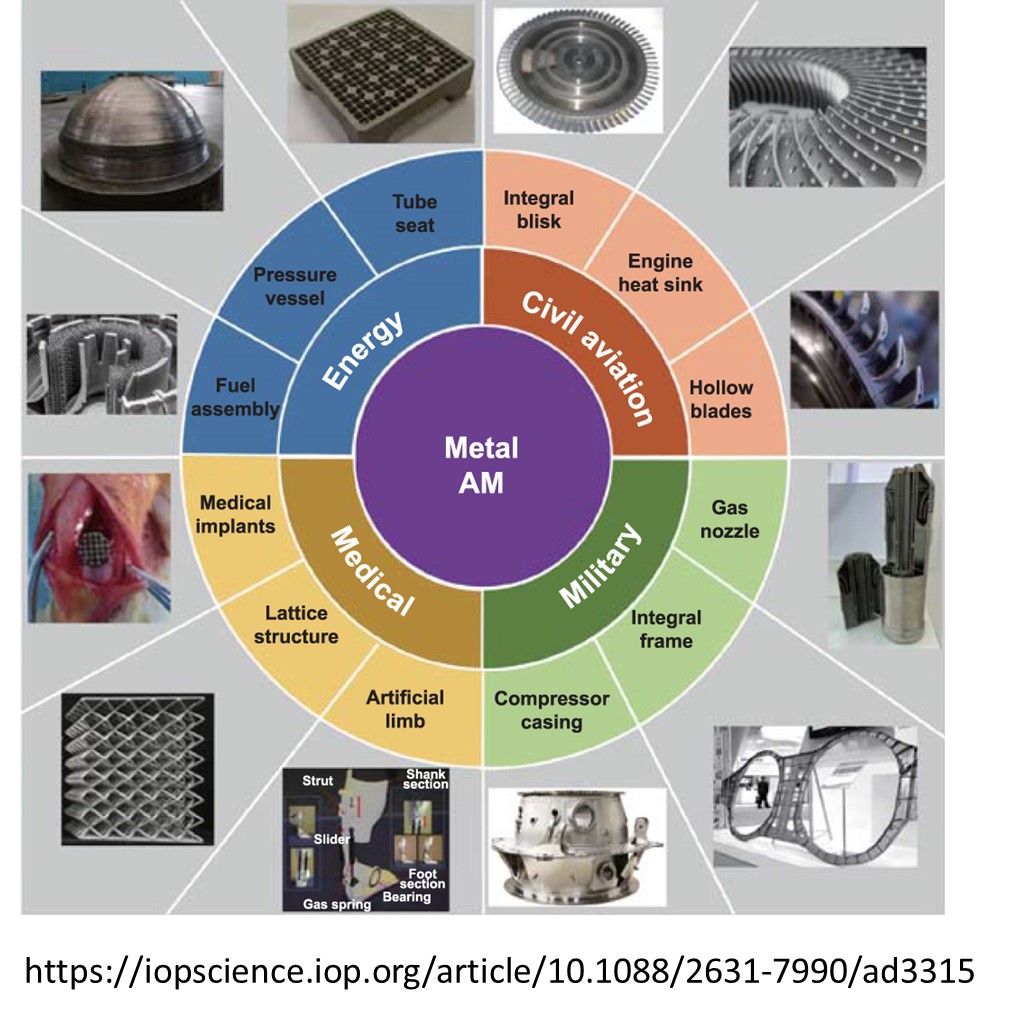

Metal Additive Manufacturing (AM) using lasers is a transformative technology that enables the layer-by-layer fabrication of complex metal components directly from digital designs. At the heart of this process is the use of high-energy laser beams, which selectively melt metal powders or wires to produce parts with exceptional precision, material efficiency, and design flexibility. Two primary laser-based metal AM techniques are Laser Powder Bed Fusion (LPBF) and Directed Energy Deposition (DED). In LPBF, a laser scans a thin layer of powder to selectively melt and fuse material, whereas in DED, the laser simultaneously melts metal powder or wire as it is deposited. Each process introduces distinct challenges related to thermal management, melt pool dynamics, and material behavior. Understanding the interaction between laser energy and metal feedstock is critical. Key parameters—such as laser power, scan speed, spot size, and wavelength—significantly influence melt pool geometry, solidification rates, microstructure development, and ultimately, the mechanical properties of the final part. To address process variability, real-time monitoring and control systems are increasingly employed to detect anomalies and enable closed-loop feedback. As metal AM advances, the integration of process simulations, multimodal sensing, and AI-driven control strategies will be vital for mastering the complex, multiscale physics involved and achieving robust, certifiable manufacturing for high-performance sectors such as aerospace, biomedical, and energy.

2. Multiscale and Multiphysics Nature

Laser-based metal additive manufacturing is governed by tightly coupled physical phenomena spanning multiple spatial and temporal scales. Key aspects include:

- 🔦 Optical Absorption & Reflection: Laser-material interaction depends heavily on the laser’s wavelength and the material’s surface absorptivity. Surface conditions—such as roughness, oxidation, or powder morphology—can dynamically alter reflectivity, leading to inconsistent energy absorption.

- 🌡️ Thermal Dynamics: Rapid and localized laser heating followed by fast cooling generates steep thermal gradients. These demand advanced thermal modeling to capture conduction, convection, and radiation effects accurately across the part and surrounding material.

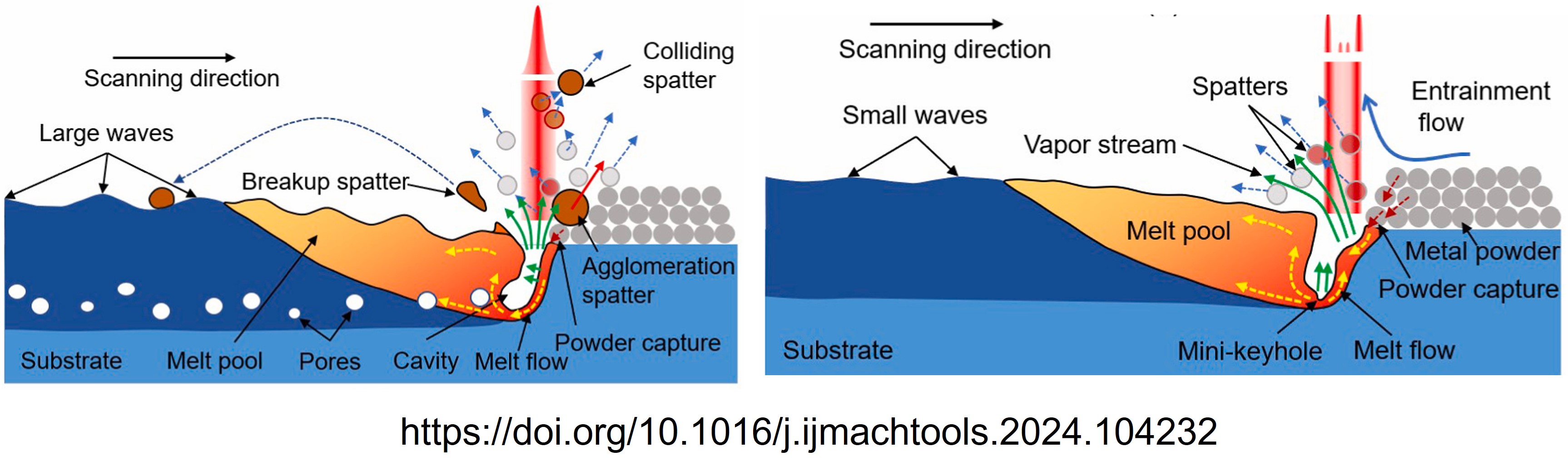

- 🌊 Fluid Flow (Melt Pool): The molten region is influenced by Marangoni convection, recoil pressure, and keyhole formation. These effects can induce melt pool instabilities, spatter, and porosity, affecting part quality and repeatability.

- ❄️ Solidification & Phase Change: The rate of cooling governs grain morphology, phase transformations, and defect formation. Fast solidification can induce residual stresses, cracks, or anisotropic microstructures, impacting mechanical performance.

3. Process-Induced Instabilities

Laser-metal interactions are prone to several dynamic instabilities that can compromise part quality:

- Vapor Plume & Plasma: Rapid vaporization generates a high-velocity recoil plume that disturbs the melt pool. At elevated energy densities, a localized plasma can form above the keyhole, attenuating the incoming laser beam and reducing effective energy coupling.

- Spattering: Intense vapor recoil and melt‐pool turbulence can eject molten droplets (spatter). These droplets may adhere to surrounding powder or substrate, creating surface defects, entrapment porosity, and material waste.

- Lack-of-Fusion / Balling: Inadequate or uneven energy input leads to incomplete fusion between adjacent tracks or layers. This can manifest as voids (lack-of-fusion) or as isolated, spheroidal beads (“balling”) that break track continuity and weaken interlayer bonding.

4. Material-Dependent Variability

Material properties play a decisive role in laser-based AM, influencing energy absorption, melt dynamics, and solidification behavior:

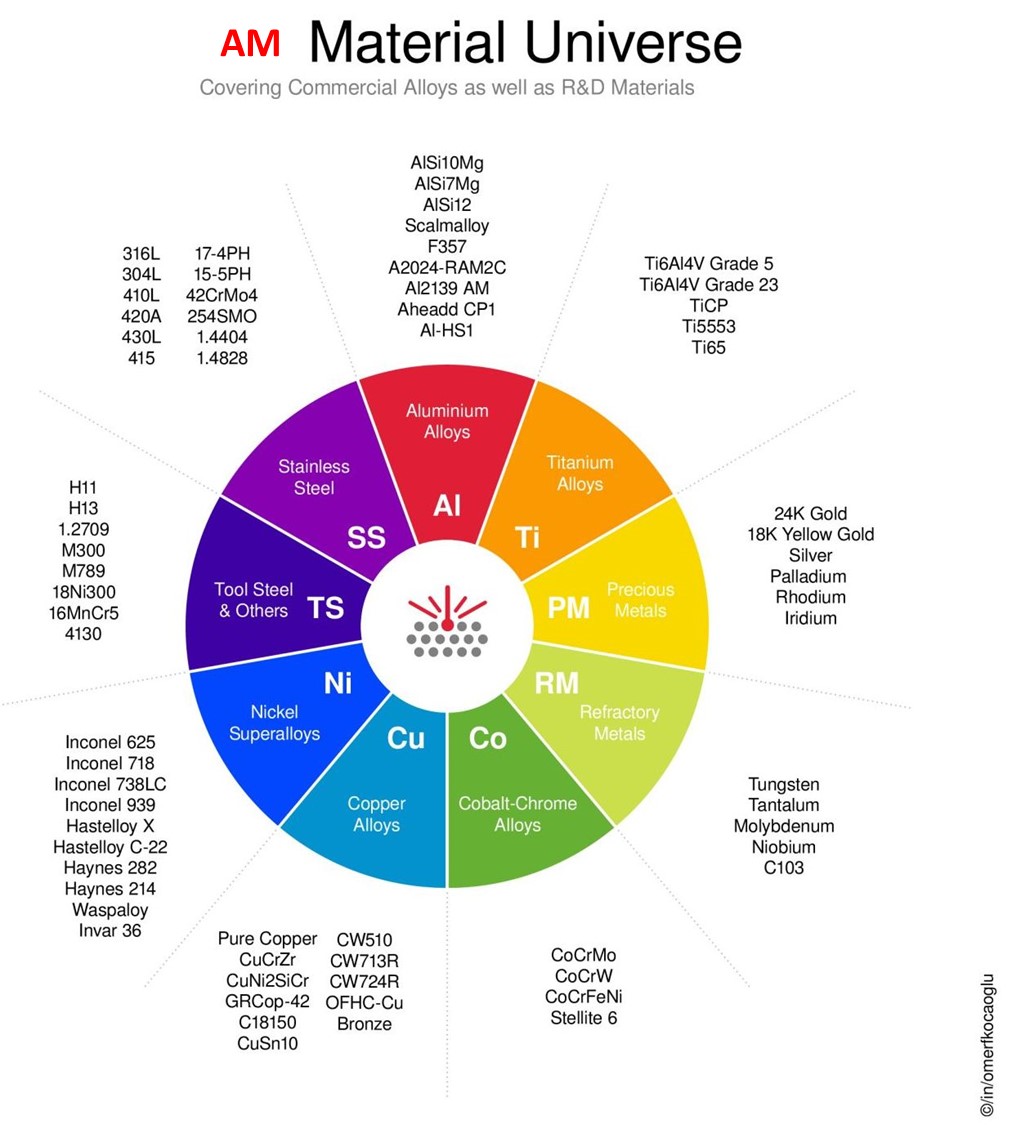

- Metals (Al, Ti, Ni, Steel): Optical absorptivity, thermal conductivity, and specific heat capacity evolve dynamically as the metal transitions from powder to liquid to solid. Alloying elements (e.g., Al in Ti-6Al-4V or Cr in stainless steel) further modulate melt viscosity, surface tension, and solidification pathways, often leading to heterogeneous microstructures and residual stress patterns.

- Ceramics & Composites: High melting points and low thermal diffusivity challenge uniform melting. Many ceramics exhibit brittle fracture upon cooling, while heterogeneous composites can suffer from differential thermal expansion and uneven laser absorption. These factors frequently induce cracking, delamination, and porosity, necessitating specialized process adaptations (e.g., preheating, tailored scan strategies).

5. Real-Time Monitoring Challenges

Effective closed-loop control in laser AM is constrained by several monitoring challenges:

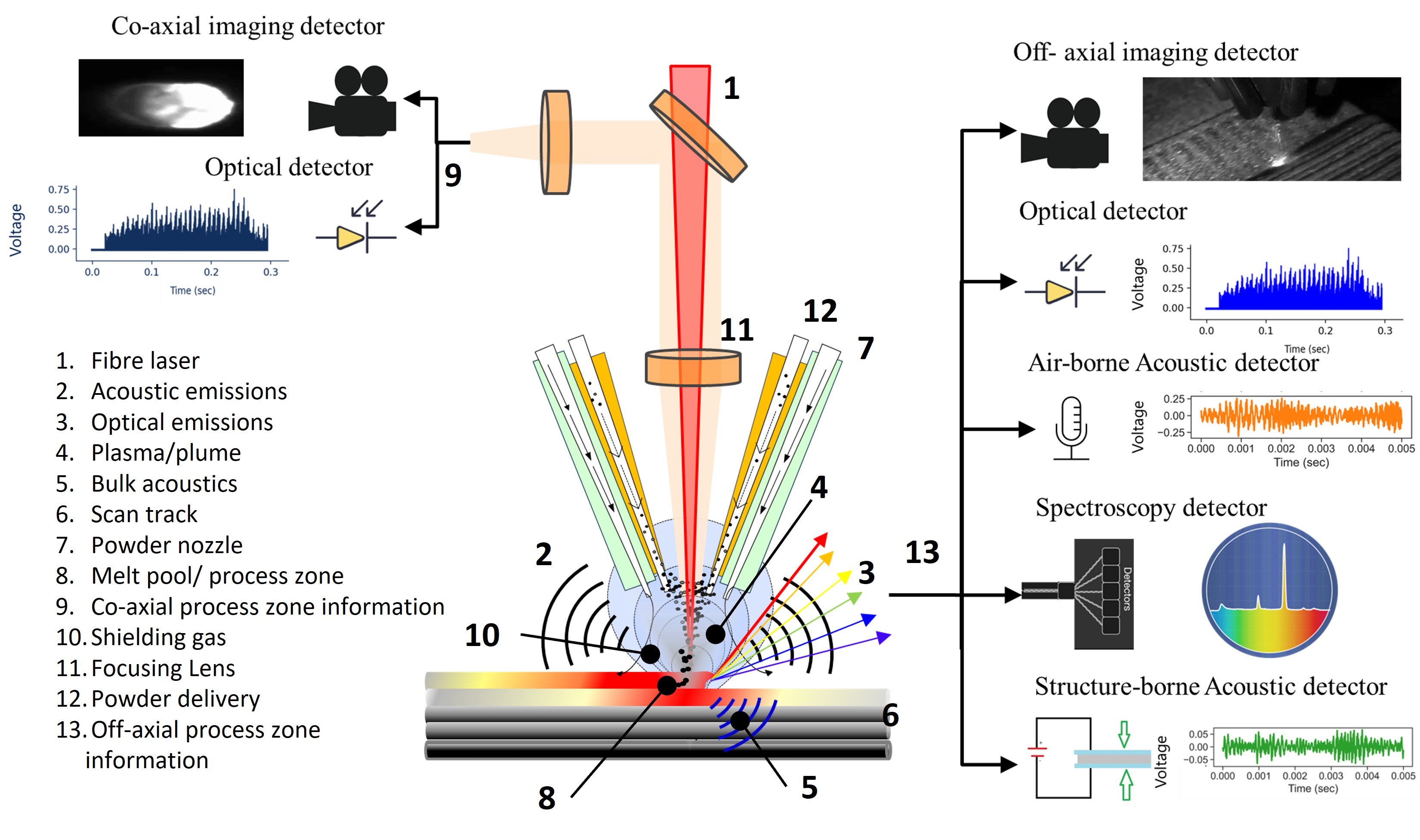

- Ultrafast Dynamics: Melt-pool and keyhole fluctuations occur on the order of microseconds to milliseconds, demanding high-speed detectors (e.g., photodiodes, high-frame-rate cameras) and real-time signal processing pipelines capable of handling gigahertz-scale data rates.

- Sensor Limitations: Optical and thermal sensors face interference from plasma emissions, spatter occlusion, and specular reflections. Calibration drift and limited dynamic range can further degrade measurement fidelity under intense process conditions.

- Feedback Latency: Delays between data acquisition, signal interpretation, and actuator response (e.g., laser power modulation or galvanometer steering) can exceed the timescale of key phenomena, making true real-time control difficult. Data-driven models and predictive controllers are therefore essential to anticipate instabilities and compensate proactively.

6. Impact on Additive Manufacturing

Laser-based AM’s complex physics and material interactions have direct consequences for industrial outcomes:

- Part Quality: Surface finish, internal density, and defect prevalence (e.g., porosity, micro-cracks) are governed by the interplay of thermal gradients, melt-pool dynamics, and material solidification. Precise control of these factors is critical for meeting stringent mechanical and metallurgical specifications.

- Process Repeatability: Variability in powder characteristics, energy coupling, and transient instabilities can lead to part-to-part and batch-to-batch inconsistencies. Robust process parameter windows and in-line monitoring are essential to tighten tolerances and reduce scrap rates.

- Scalability: To transition from prototypes to mass production, AM systems must deliver high throughput without sacrificing accuracy or defect control. Achieving this balance requires optimized scan strategies, adaptive control algorithms, and modular hardware capable of maintaining performance across larger build volumes.

7. Conclusion & Future Directions

Laser–material interactions in metal AM represent a nexus of interdependent phenomena—laser radiation absorption and reflection, transient heat conduction and convection, melt‐pool hydrodynamics (including Marangoni flows and recoil‐pressure–driven keyholing), rapid solidification kinetics, and the resultant stress–strain evolution. Quantitative mastery of these coupled processes—through high‐fidelity multiscale modeling that bridges electronic‐scale absorptivity changes to continuum‐scale thermal fields, real‐time, multimodal diagnostics capable of resolving melt‐pool morphology on microsecond timescales, and closed‐loop, AI‐augmented control strategies that dynamically tune laser parameters—enables precise regulation of energy deposition and solid‐state transformations. Such integrated control yields parts with tailored microstructures, minimized porosity and residual stresses, and reproducible mechanical performance, laying the scientific foundation for scalable, certifiable, and high‐throughput metal additive manufacturing.

- Multiscale Multiphysics Modeling: Concurrently resolve atomistic diffusion, dendritic solidification kinetics, and continuum-scale heat flow to predict microstructural features and residual stress evolution with high fidelity.

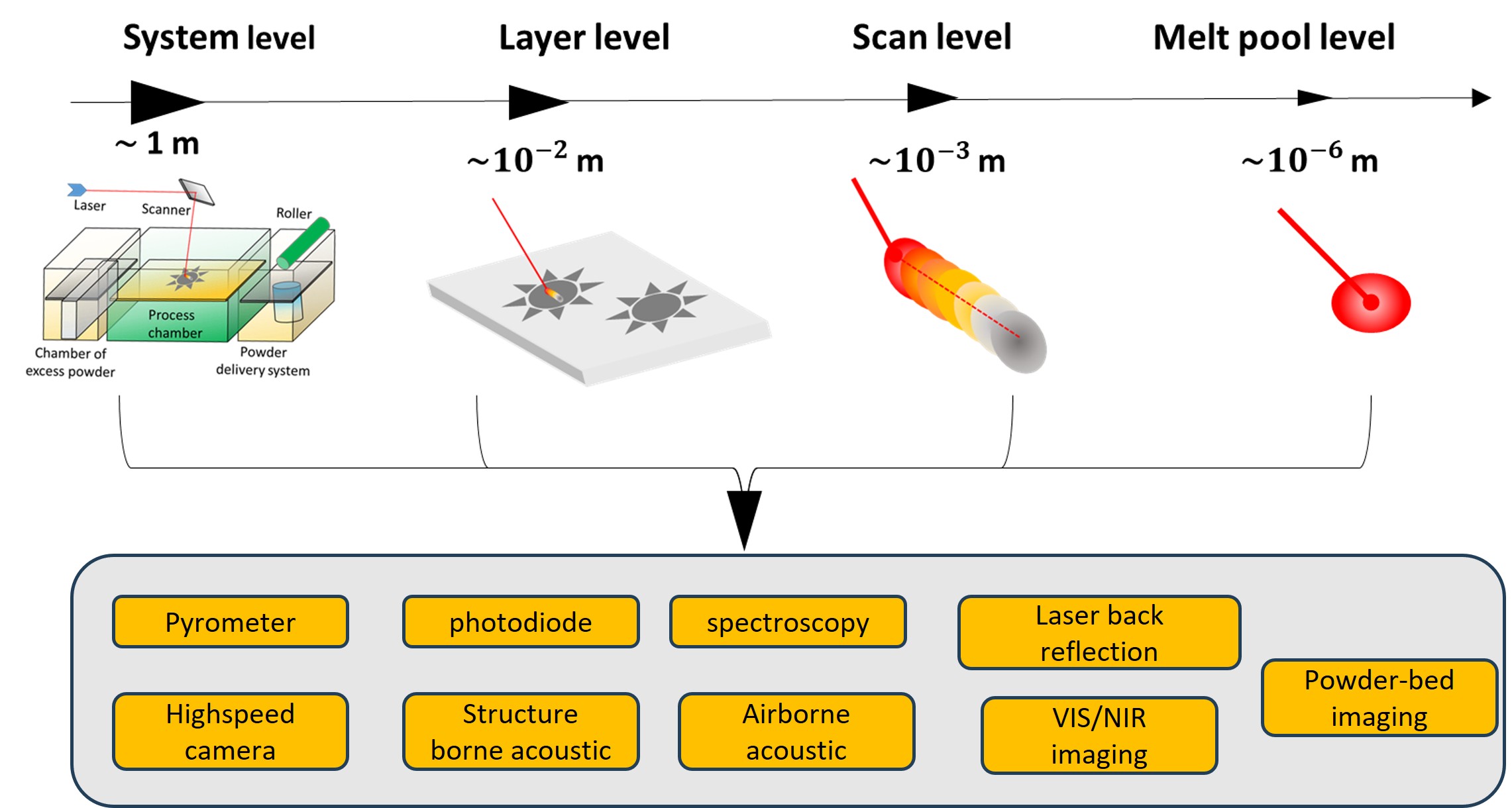

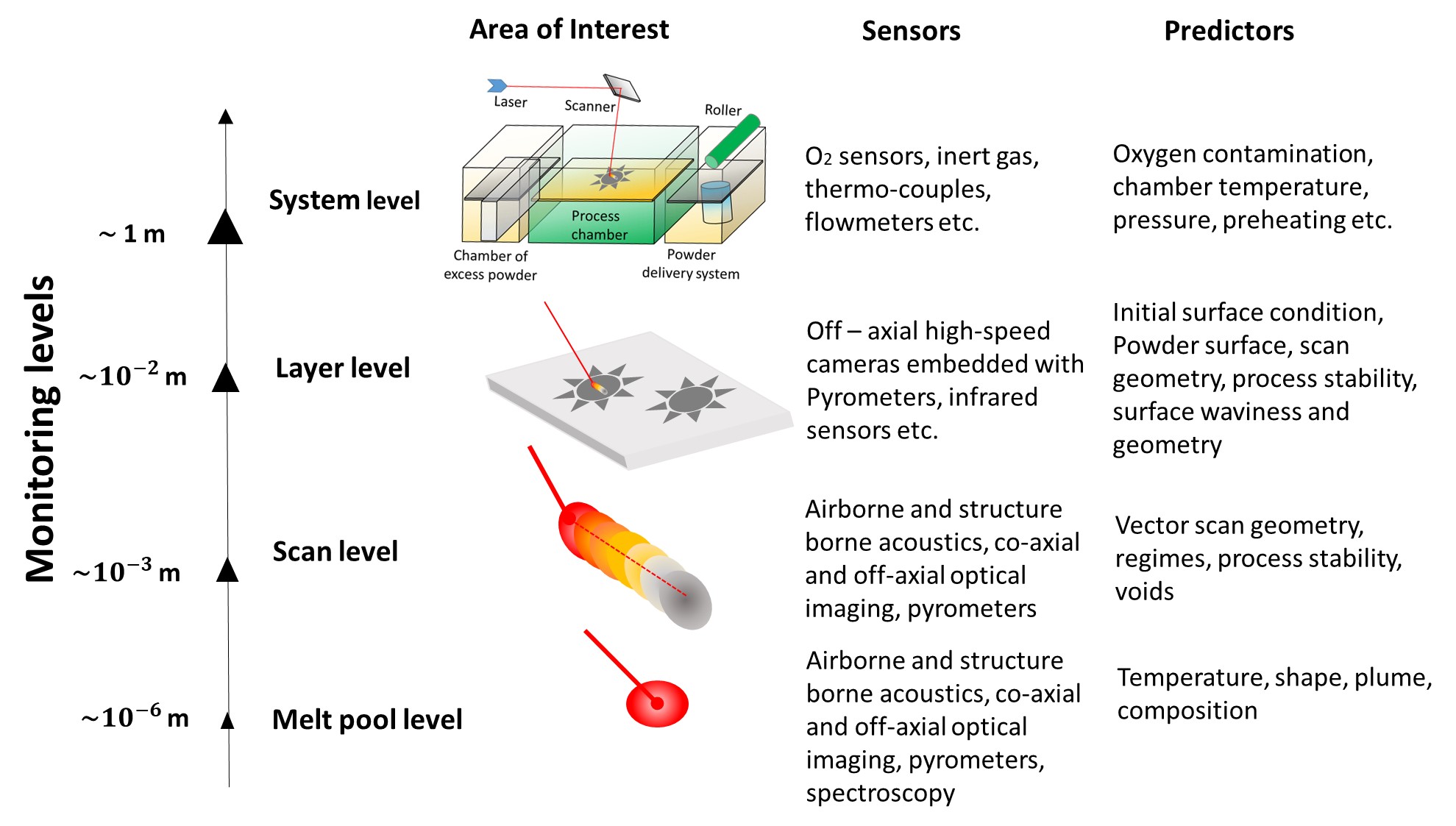

- Real-Time Multimodal Sensing: Deploy synchronized high-speed photodiodes, spectral pyrometers, and acoustic emission sensors, integrated via data-fusion frameworks, to characterize melt-pool geometry and detect nascent defects on microsecond timescales.

- Closed-Loop AI-Based Control: Implement predictive deep-learning models and model-predictive control algorithms that adjust laser power, scan velocity, and beam shaping in situ, preempting keyholing, spatter, and lack-of-fusion events.

- Adaptive Laser Modulation: Utilize ultrafast pulse shaping, dynamic wavelength selection, and spatial beam intensity modulation to tailor energy deposition profiles, optimize melt-pool hydrodynamics, and refine solidification fronts.

8. References

- Differentiation of materials and laser powder bed fusion processing regimes from airborne acoustic emission combined with machine learning

- Semi-supervised Monitoring of Laser powder bed fusion process based on acoustic emissions

- Analysis of time, frequency and time-frequency domain features from acoustic emissions during Laser Powder-Bed fusion process

- Artificial Intelligence for Monitoring and Control of Metal Additive Manufacturing

- Optimizing In-situ Monitoring for Laser Powder Bed Fusion Process: Deciphering Acoustic Emission and Sensor Sensitivity with Explainable Machine Learning

- In situ quality monitoring in direct energy deposition process using co-axial process zone imaging and deep contrastive learning

- Monitoring Of Laser Powder Bed Fusion Process By Bridging Dissimilar Process Maps Using Deep Learning-based Domain Adaptation on Acoustic Emissions

- Harmonizing sound and light: X-ray imaging unveils acoustic signatures of stochastic inter-regime instabilities during laser melting

- Monitoring of functionally graded material during laser directed energy deposition by acoustic emission and optical emission spectroscopy using artificial intelligence

- Real-time monitoring and quality assurance for laser-based directed energy deposition: integrating co-axial imaging and self-supervised deep learning framework

- Self-Supervised Bayesian representation learning of acoustic emissions from laser powder bed fusion process for in-situ monitoring

- Qualify-as-you-go: sensor fusion of optical and acoustic signatures with contrastive deep learning for multi-material composition monitoring in laser powder bed fusion process

- Investigating laser beam shadowing and powder particle dynamics in directed energy deposition through high-fidelity modelling and high-speed imaging

- Deep transfer learning of additive manufacturing mechanisms across materials in metal-based laser powder bed fusion process