Abrasive Finishing

🔧 How Do Abrasive-Workpiece Interactions Modify Material Structure at Different Scales?

📘 1. Introduction

Abrasive finishing processes—such as grinding, polishing, and lapping—drive intricate surface and subsurface material transformations that dictate component performance. These transformations influence:

- ✅ Surface Integrity:

- Topography: The interaction of individual abrasive grains with surface asperities generates a characteristic roughness profile.

- Residual Stress: Mechanical deformation and localized heating introduce tensile or compressive stresses in the near-surface region, affecting crack initiation.

- Microstructural Alterations: Severe plastic deformation can refine grains, induce work hardening, or create white-etch layers in steels.

- ✅ Functional Performance:

- Wear Resistance: A smoother, work-hardened surface can better resist adhesive or abrasive wear.

- Fatigue Life: Compressive residual stresses often enhance fatigue strength, whereas tensile stresses or micro-cracks reduce it.

- Corrosion Behavior: Surface finishing can remove inclusions or alter passive film formation, impacting corrosion rates.

- ✅ Process Efficiency:

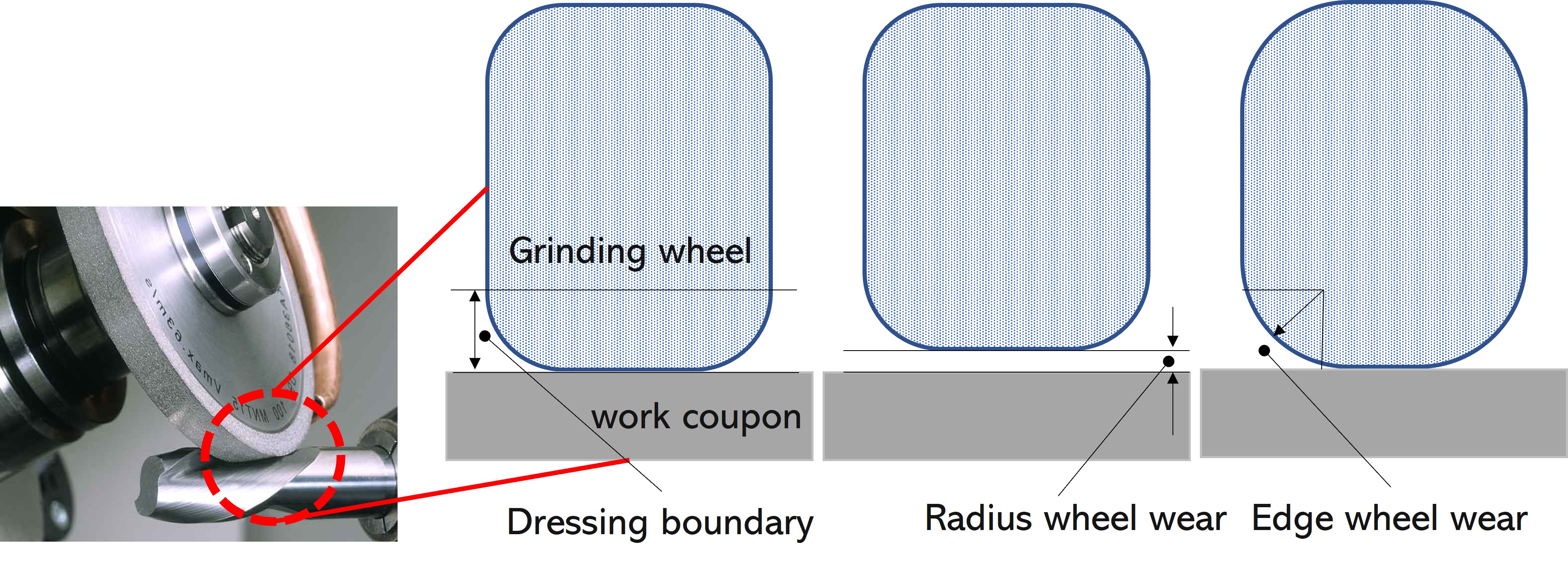

- Tool Wear: Abrasive grain fracture and binder degradation change cutting geometry over time, requiring dressing or wheel replacement.

- Energy Consumption: Frictional heating and material removal rates determine power draw and thermal loads.

- Throughput: Optimizing feed rates, wheel speed, and depth of cut balances stock removal with surface quality.

Key Question: How do the mechanical and thermal interactions between abrasive grains and the workpiece modify material structure across length scales—from individual asperity contacts (micron scale) through the plastically deformed subsurface zone (tens of microns) to the bulk microstructure (millimeter scale)??

To address this, we must:

- Characterize Grain–Surface Contact Mechanics: Quantify cutting versus plowing regimes, chip formation processes, and local temperature rise at single-grain contacts.

- Map Subsurface Effects: Use cross-sectional microscopy and microhardness profiling to reveal plastically deformed layers, work-hardened zones, and thermal-affected microstructures.

- Link to Bulk Performance: Correlate measured surface and subsurface states with macroscopic performance metrics such as fatigue life, wear rate, and corrosion resistance.

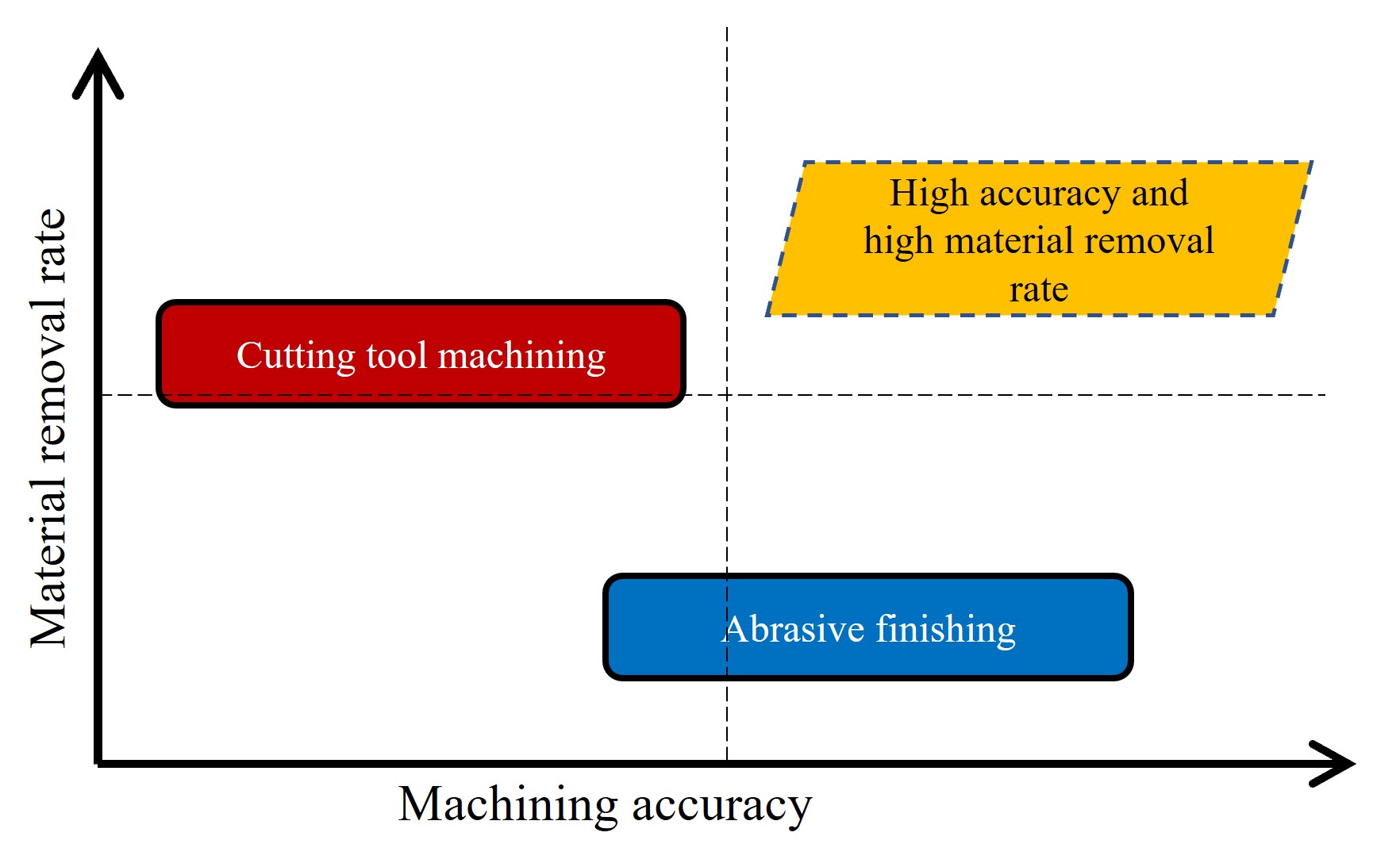

By systematically dissecting these interactions, we can develop predictive models and closed-loop control strategies that optimize abrasive finishing for both precision and efficiency.

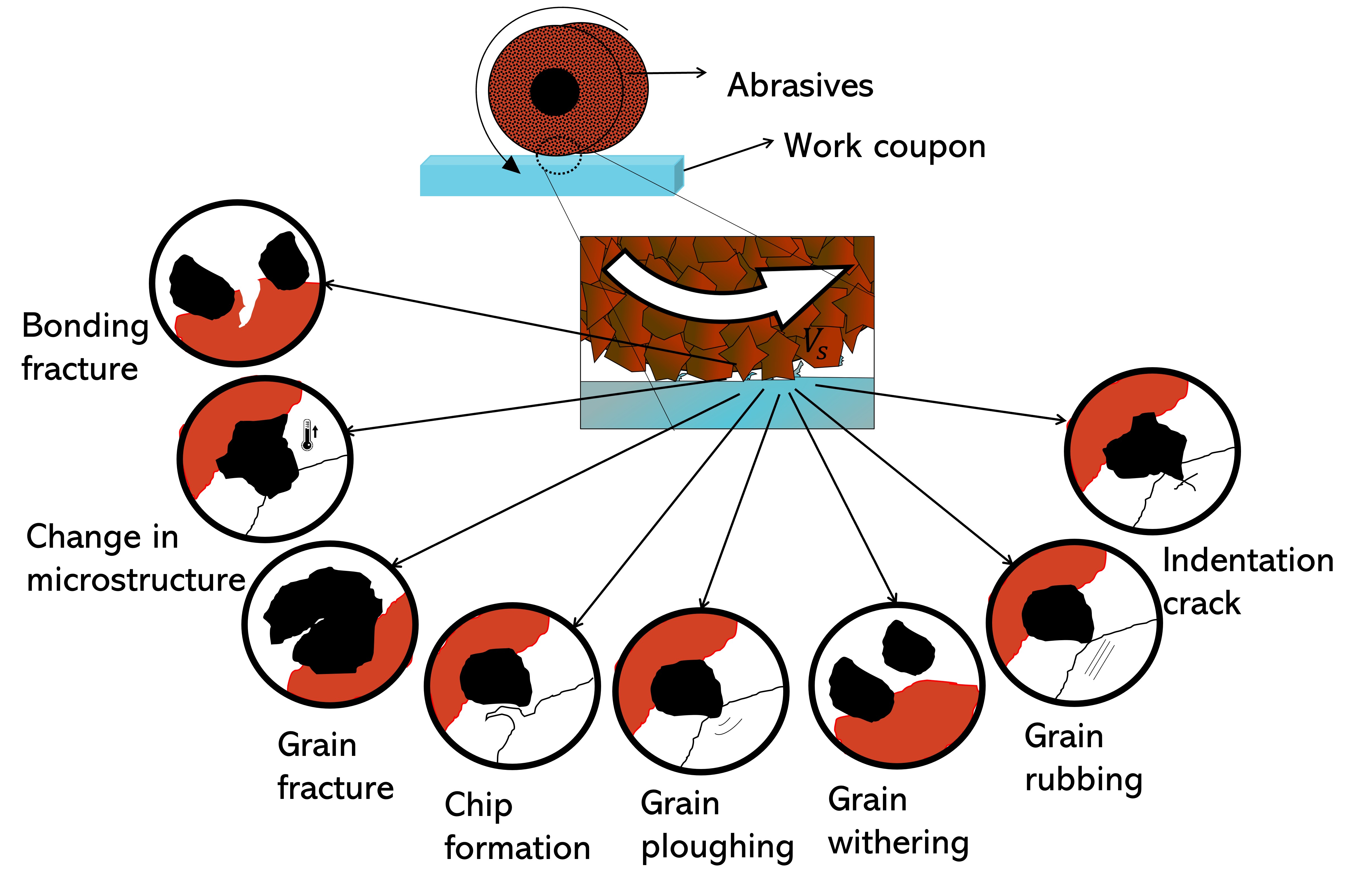

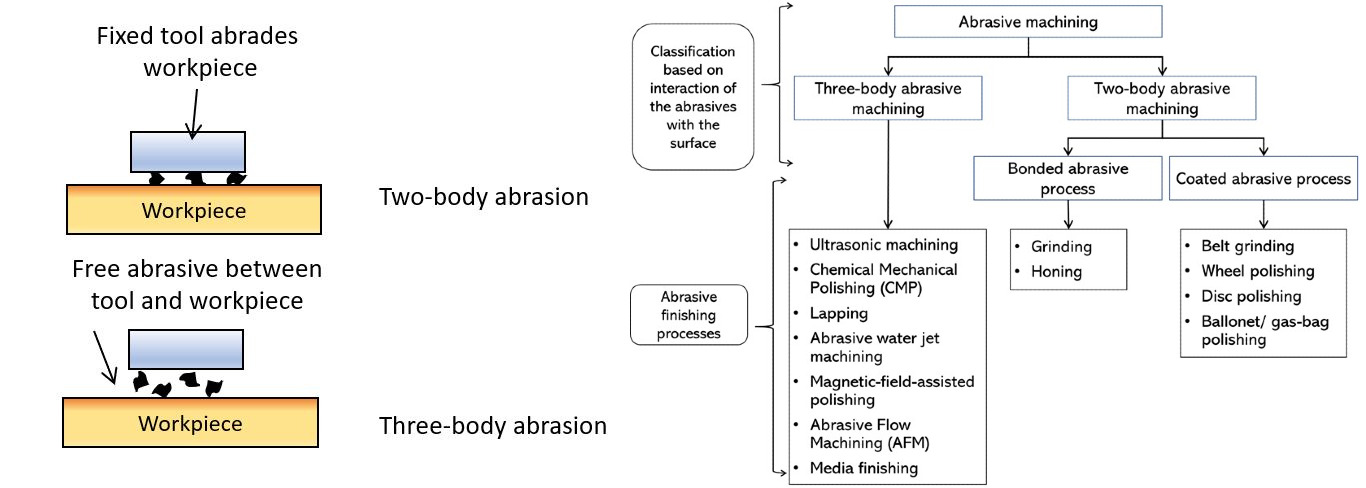

2. Material Removal Mechanisms

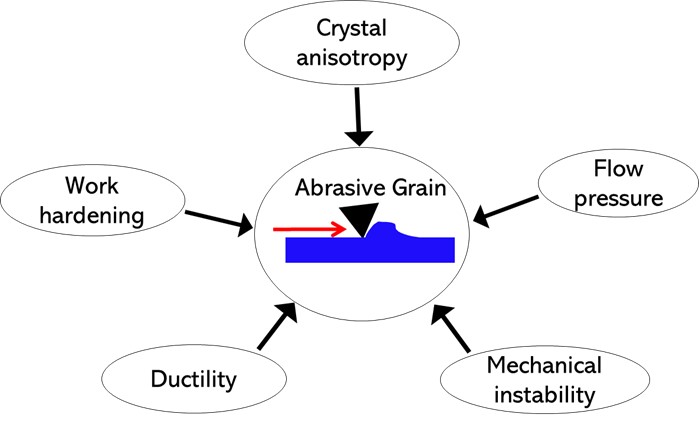

Abrasive finishing relies on two fundamental modes of interaction between abrasive grains and the workpiece surface: cutting & plowing and micro-fracture. Each mechanism is governed by the relative hardness of grain versus workpiece, the applied load, and the kinematics of the process.

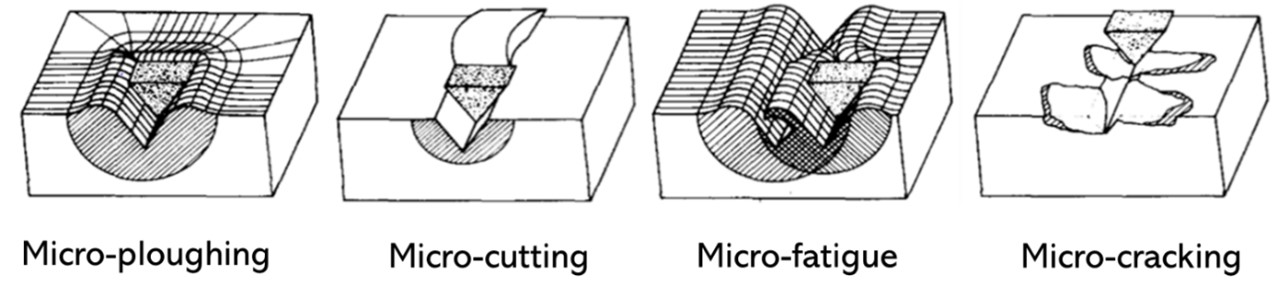

2.1 🔪 Cutting & Plowing

- Chip Formation

- When a grain’s cutting edge penetrates the surface beyond a critical depth, it severs material in the form of chips. The chip morphology—continuous, segmented, or powdery—depends on material ductility and cutting conditions.

- The Merchant model relates the chip thickness and shear angle to the grain geometry and process forces, allowing prediction of cutting forces and energy consumption.

- Plowing and Smearing

- If penetration is shallow or the material is more ductile than the grain hardness, the abrasive pushes rather than shears, displacing material sideways and creating ridges and a smeared surface layer rather than discrete chips.

- Plowing generates higher friction and heat, often leading to work hardening in the near-surface zone and greater plastic deformation relative to material removal.

- Transition Criterion

- The critical depth of cut marks the threshold between cutting and plowing, as a function of material fracture toughness, hardness ratio, and abrasive geometry.

- Controlling depth of cut and grain protrusion ensures consistent chip formation, minimizes excessive smearing, and optimizes surface finish.

2.2 Micro‐fracture

- Crack Initiation

- In brittle or hard materials (e.g., ceramics, hardened steels), abrasive impacts can exceed fracture toughness, initiating radial and lateral cracks beneath the contact zone.

- Indentation fracture mechanics describe the stress field around a single grain, predicting crack lengths based on applied load and material toughness.

- Chip Detachment

- Once cracks propagate and intersect, small fragments spall away from the surface. These micro-fracture chips are irregular in shape and size, often contributing to a matte or frosted surface appearance.

- The rate of fragment detachment depends on impact frequency, grain size distribution, and material brittleness.

- Surface Damage & Subsurface Cracks

- Excessive micro-fracture can leave subsurface cracks that act as fatigue initiation sites, so balancing fracture-driven removal with subsequent polishing is critical.

- Process parameters (lower normal loads, finer grit sizes) and sequential abrasive grades transition from fracture-dominated stock removal to ductile-dominated finishing.

By understanding and controlling these mechanisms—through grain selection, process kinematics, and load management—engineers can tailor material removal to achieve desired surface characteristics while minimizing adverse subsurface damage.

🧬 3. Types of Material Transformations

🔬 3.1 Microstructural Changes

- Grain refinement: formation of nanocrystalline surface layers via severe plastic deformation.

- Phase transformations: e.g., austenite → martensite in steels under high strain and rapid cooling.

- Twinning & dislocation networks: accumulation of crystallographic twins and dislocation structures as primary plasticity mechanisms.

- Ductile vs. brittle removal:

- Ductile mode: dominated by plastic flow, potential local amorphization, smooth chip formation.

- Brittle mode: characterized by crack initiation and propagation, resulting in fragmented chips and rough surfaces.

⚡ 3.2 Thermomechanical Effects

- Localized heating: friction-induced temperature spikes at asperity contacts can exceed 1,000 °C.

- Recrystallization & dynamic recovery: high-strain-rate deformation triggers new grain formation and dislocation annihilation.

- White layer formation: hard, brittle rehardened zones caused by rapid surface quenching.

- Flash temperatures & surface reactivity: transient plasma (“triboplasma”) and exo-emissions modify surface chemistry.

- Grinding burns: thermal overload leads to surface discoloration and subsurface rehardening (detected via nital etch).

- Heat-affected zones (HAZ): extended thermal fields induce tensile residual stresses and potential microcracking.

🧪 3.3 Tribochemical Reactions

- Oxide layer formation: e.g., rapid Al₂O₃ growth on aluminum surfaces, altering friction and wear behavior.

- Hydrogen embrittlement: adsorption of hydrogen in reactive environments leading to crack susceptibility.

- Tribofilm generation: self-assembled, lubricious films (oxides, sulfides) that reduce friction and wear.

- Magma–plasma model: explains rapid activation of chemical reactions under extreme contact temperatures and pressures.

- Lubricant-induced films: polar additives bond chemically to metal surfaces, forming protective boundary layers for high-pressure sliding.

🚧 4. Research Challenges & Complexities

4.1 Multiscale Interactions

- Macroscale: Bulk process forces, overall heat generation, and thermal gradients across the workpiece.

- Microscale: Grain‐boundary sliding, localized phase transformations, and evolving residual stresses in the subsurface.

- Nanoscale: Dislocation nucleation and motion, amorphization, and triboactivated chemical processes at asperity contacts.

4.2 Process Stochasticity

- Randomized grit–workpiece contacts lead to nonuniform material removal and energy input.

- Abrasive grain wear and fracture alter cutting mechanics over time, complicating process stability.

- Chemo‐mechanical synergy (simultaneous mechanical deformation and surface chemistry) adds unpredictability.

- Coolant & Lubricant Effects:

- Oil‐based lubricants increase normal force on grains but reduce friction and heat.

- Water‐based coolants enhance dimensional accuracy and mitigate thermal stresses.

4.3 Characterization Difficulties

- In situ observation is hindered by the need for high‐speed, high‐resolution imaging of subsurface phenomena.

- Residual stress measurement techniques (e.g., X-ray diffraction vs. FIB-DIC) involve trade-offs between penetration depth and spatial resolution.

- Actual contact area can exceed nominal by 10–1000× due to asperity interactions, challenging force and wear models.

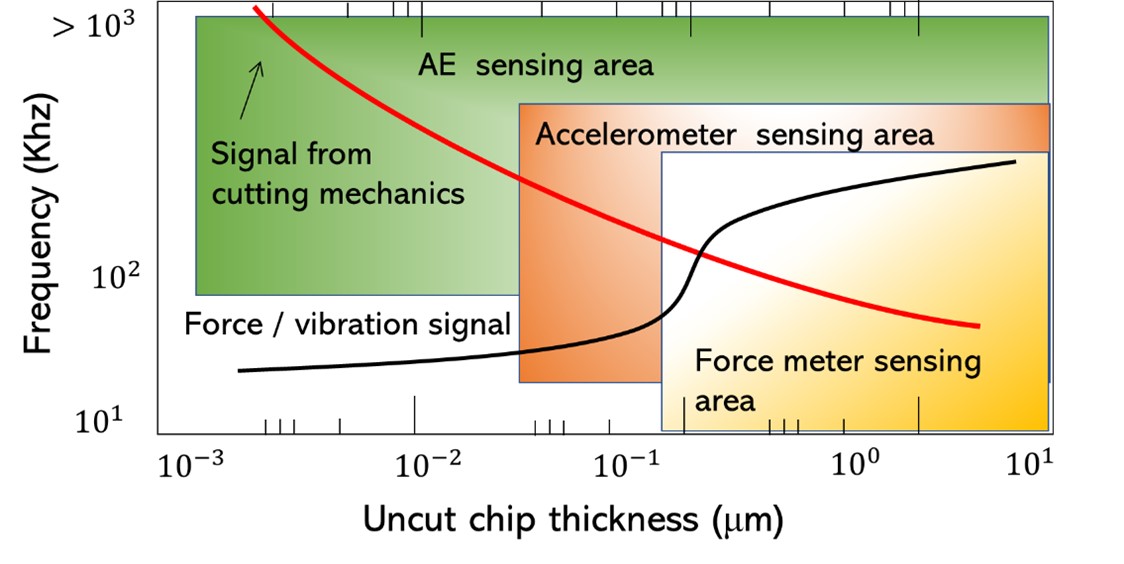

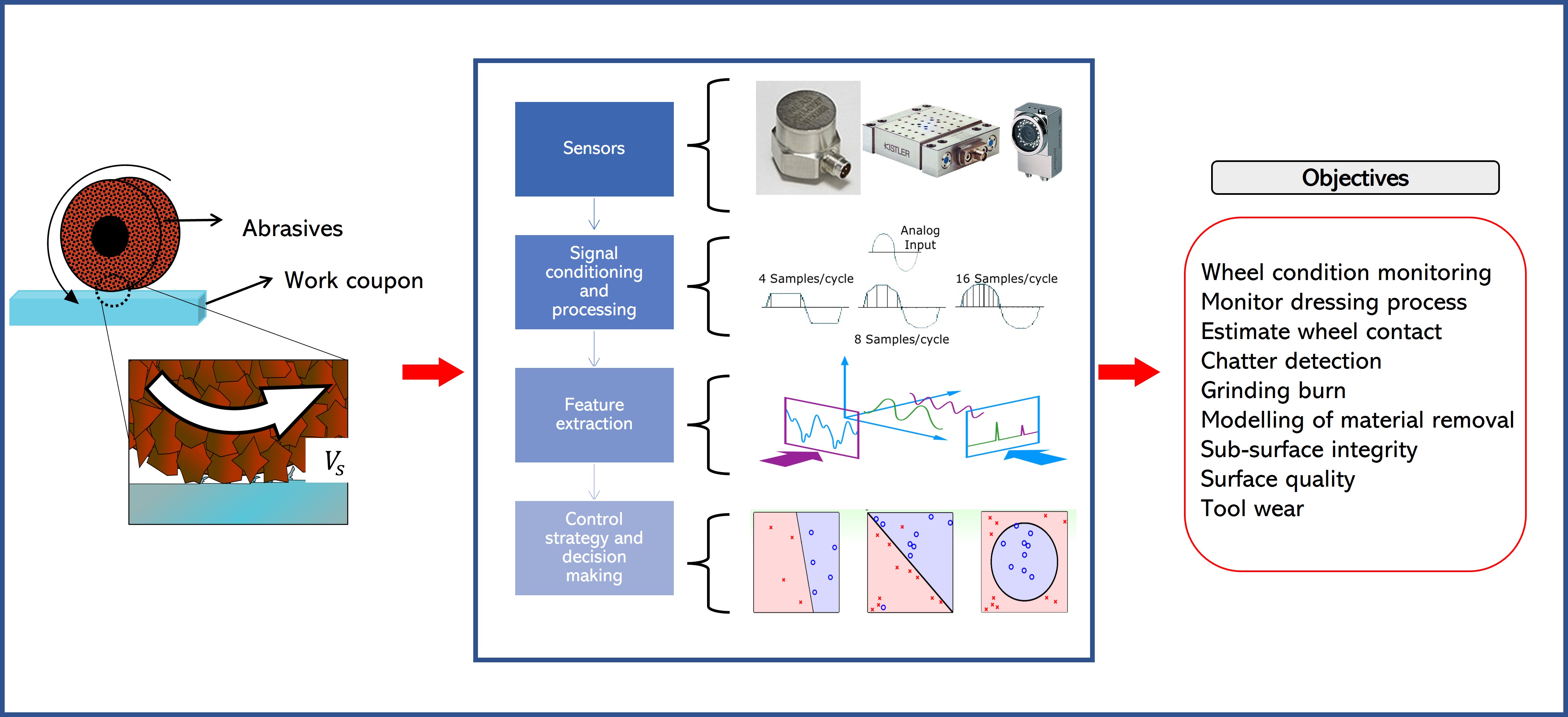

- Acoustic Emission Sensors provide real-time detection of tool wear and chatter, unaffected by thermal drift.

- Piezoelectric Force Sensors accurately monitor grinding forces and vibrations with high sensitivity.

💡 5. Open Research Questions

| Topic | Key Challenges | Potential Solutions |

|---|---|---|

| Nanoscale Deformation | Dislocation nucleation mechanisms | MD simulations + TEM tribometry |

| Phase Stability | Metastable phase retention | Synchrotron X-ray diffraction |

| Tribofilm Control | Reaction kinetics in lubricants | In-situ Raman spectroscopy |

| Residual Stress Prediction | Multiaxial stress coupling | Hybrid FEM-analytical models |

| Triboplasma Effects | High energy contact reactions | Flash temperature models + spectroscopy |

🚀 6. Emerging Research Directions

6.1 Advanced Characterization

- In situ TEM scratching for real-time observation of deformation mechanisms.

- X-ray computed tomography (XCT) for three-dimensional mapping of subsurface damage.

- Exo-emission detection of photons and electrons during abrasive contact for chemical and tribological insights.

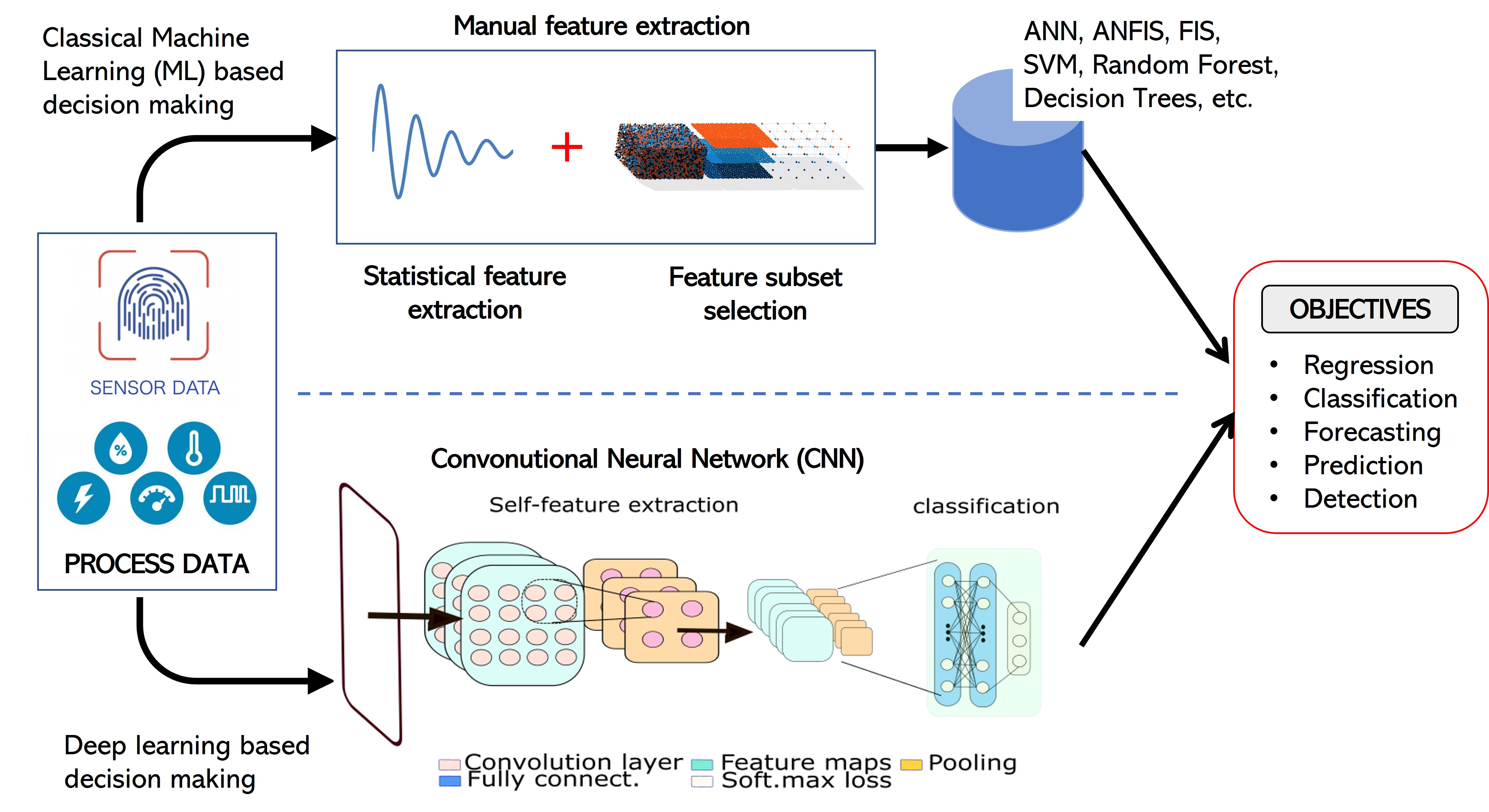

6.2 AI & Digital Twins

- Machine learning algorithms for adaptive process optimization and parameter tuning.

- Physics-informed neural networks (PINNs) for high-fidelity stress and temperature prediction.

- Integrated process simulation chain: Modeling → Simulation → Experimental Validation → Optimization.

- AI-based monitoring: Neural networks analyze acoustic emission, spindle load, and vibration data to predict tool wear, surface finish, and grinding burn risk in real-time.

6.3 Sustainable Finishing

- Bio-inspired abrasives leveraging natural microstructures for energy-efficient material removal.

- Electrochemically-assisted finishing and hybrid mechanical–electrochemical processes for reduced environmental impact.

- Chemo-mechanical polishing (CMP) techniques tailored for advanced ceramics and semiconductor substrates.

🔚 7. Conclusion

The complexity of abrasive finishing arises from the interplay of mechanical cutting, plastic deformation, fracture, and tribochemical phenomena across multiple length scales. Achieving predictable and optimized surface outcomes requires a holistic strategy that unites advanced diagnostics, mechanistic modeling, and eco-conscious process design:

- 🔹 High-resolution in-situ characterization: Leverage real-time TEM, XCT, and exo-emission techniques to capture transient deformation, crack initiation, and subsurface phase changes with nanometer resolution.

- 🔹 Physics-based modeling with AI augmentation: Develop multiscale simulations that integrate discrete grain–surface contact mechanics, continuum thermal–mechanical finite-element models, and machine-learning surrogates to predict surface integrity under varying parameters.

- 🔹 Sustainable process development: Design bio-inspired and hybrid electrochemical–mechanical finishing methods that minimize energy consumption, reduce waste, and extend abrasive tool life while maintaining stringent surface quality standards.

- 🔹 Incorporating triboplasma and tribochemical insights: Embed chemical reaction models driven by flash temperatures and triboplasma activation into predictive frameworks to control oxide film formation, lubrication film dynamics, and surface chemistry evolution.

Call to Action: Integrating these approaches can close the gap between fundamental research and industrial practice. What integrated workflows and cross-disciplinary collaborations are needed to accelerate the adoption of predictive, sustainable abrasive finishing in manufacturing environments?

📚 8. References

- Use of Acoustic Emissions to Detect Change in Contact Mechanisms Caused by Tool Wear in Abrasive Belt Grinding Process

- Predictive Modelling and Analysis of Process Parameters on Material Removal Characteristics in Abrasive Belt Grinding Process

- In-process Virtual Verification of Weld Seam Removal in Robotic Abrasive Belt Grinding Process Using Deep Learning

- Modelling and Monitoring of Abrasive Finishing Processes Using Artificial Intelligence Techniques: A Review

- In-process Tool Condition Monitoring in Compliant Abrasive Belt Grinding Process Using Support Vector Machine and Genetic Algorithm

- Modelling and In-process Monitoring of Abrasive Belt Grinding Process

- Analysis of Contact Conditions Based on Process Parameters in Robotic Abrasive Belt Grinding Using Dynamic Pressure Sensor

- In-process Surface Roughness Estimation Model for Compliant Abrasive Belt Machining Process

- A CNN Prediction Method for Belt Grinding Tool Wear in a Polishing Process Utilizing 3-Axes Force and Vibration Data

- High Frequency and Amplitude Effects in Vibratory Media Finishing

- In-process Endpoint Detection of Weld Seam Removal in Robotic Abrasive Belt Grinding Process

- Modelling of Material Removal in Abrasive Belt Grinding Process: A Regression Approach

- Experimental Investigation of High Frequency Media Finishing Process